Electrical insulating tape

Electrical insulating tape

INSUTPE-EL-BLACK-15MMX10M

Register now and access more than 125,000 products

VDE-tested in accordance with DIN EN 60454-3-1 Type 5

- Safe thanks to tested properties

- Up to 40 kV/mm dielectric strength

- Flame-retardant

Safe and easy to use

- Tear-proof and resistant to ageing

- High degree of flexibility and adhesive strength

- Excellent moulding to different shapes

- High level of dielectric strength and mechanical protection

Permanent material properties even at changing and low temperatures

Highly resistant to diluted acids and alkalis

Protect the tape from exposure to direct sunlight and solvent vapours.

VDE-tested in accordance with DIN EN 60454-3-1 Type 5

Complies with:

- Standard BS3924

- European Directive 2011/65/EC (RoHS 2)

- Commission Delegated Regulation (EU) 2015/863 (RoHS 3)

- EU Directive 2000/53 (free from lead, chromium VI, mercury and cadmium)

The usage instructions are recommendations based on the tests we have conducted and our experience; carry out your own tests before each application. Due to the large number of applications and storage and processing conditions, we do not assume any liability for a specific application result. Insofar as our free customer service provides technical information or acts as an advisory service, no responsibility is assumed by this service except where the advice or information given falls within the scope of our specified, contractually agreed service or the advisor was acting deliberately. We guarantee consistent quality of our products. We reserve the right to make technical changes and further develop products.

Datasheets(X)

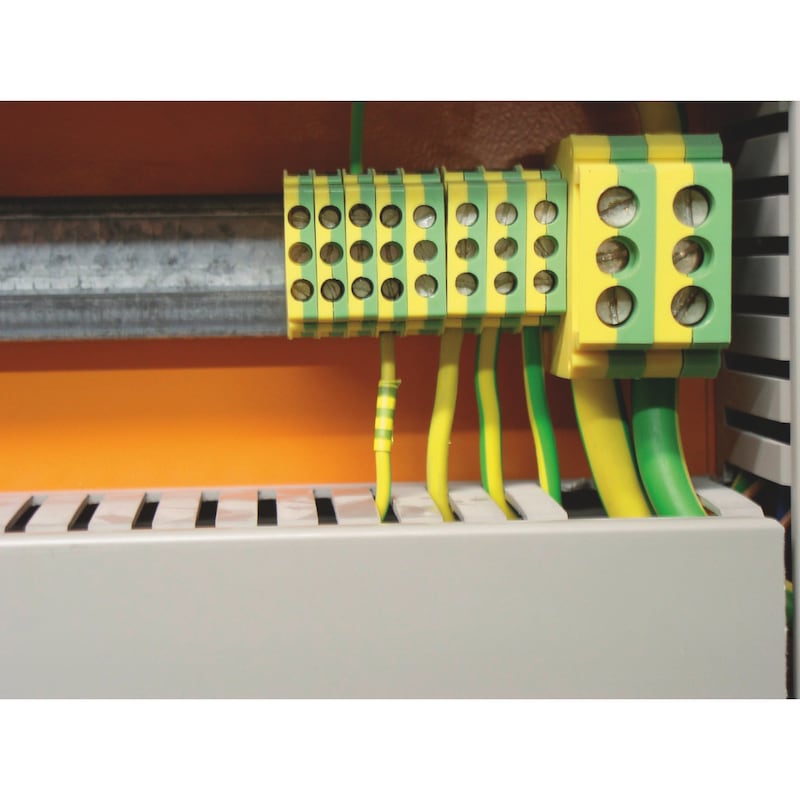

For insulating and bundling cables, wires, connections and fasteners, wrapping cables, securing cable harnesses, manufacturing cable harnesses, protecting low- and medium-voltage cable splices etc. Also ideal for marking electrical cables and for repairing damaged insulation or cable sheaths.

The surfaces must be solid, clean, dry and free from grease and oil. The tape must be tensioned in such a way that it guarantees optimal binding and wrapping by at least two layers overlapping halfway. Less tension should be applied to the final layer to prevent the layers effectively from becoming one.